Introduction

The world of manufacturing is evolving. Businesses are seeking to get more output in less time, cheaper, and quality components. The conventional techniques of molding may prove to be lengthy and costly. This is the reason why repmold solutions are selected by many industries. The process is used in modern days to generate good, reliable, and repeatable components without waste of time and materials.

In automotive and aerospace up to medical and consumer product, repmold technology is capable of flexible production and easy scaling. This guide will reveal how it operates, why it is important as well as how businesses use it to remain competitive in the global arena.

What Is Repmold

Simple Definition

Repmold is a repeatable molding that is employed to create the same parts with great accuracy. It is oriented to rapid reproduction, regularity of outcomes, and minimum usage of materials.

Why It Matters

Manufacturers require systems which minimize errors and prompt production. This process makes sure that all the parts resembled the original design. It translates to reduced defects, reduced cost, and customer satisfaction.

Read More Like: 5starsstocks.com 3d printing stocks

How Repmold Works

Design Phase

A digital model is developed by engineers through the use of CAD software. The construction consists of size, shape and performance specification. Accuracy at this phase eliminates difficulties in the future.

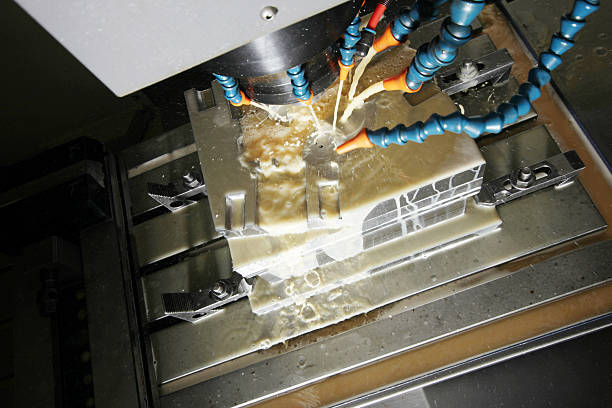

Mold Creation

Mothers that are good are constructed with high materials like aluminum or steel. The mold should be able to process heat, pressure and repetition cycles.

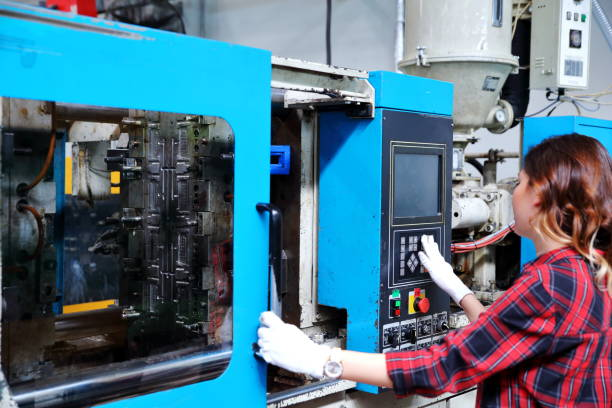

Replication Process

The mold is injected or pressed with material. The finished part is then removed after cooling or curing. Repmold is very efficient because of its ability to recycle the same mold multiple times.

Quality Control

These sections are verified. This maintains uniformity in terms of large production batches.

Key Benefits of Repmold

Faster Production

The process favours the speedy cycles. Firms are able to design numerous components within a limited period and this assists in dealing with strict schedules.

Lower Costs

Molds which are reused save on tooling costs. Waste will also be reduced hence savings made on raw materials.

High Precision

All of the components are almost the same. This precision enhances assembly and performance of products.

Scalability

Small business can be initiated and expanded with ease. Repmold deals with mass production and prototypes.

Material Flexibility

It can be done using different plastics, resins, and composite. This provides the manufacturers with the liberty of deciding on the most appropriate option.

Read More Like: Slylar Box

Industries That Use Repmold

Automotive

Automobile producers require tough and less heavy components. Repmold promotes dashboards, paneling, and internal parts of a uniform quality.

Medical

Medical equipment and device cases have to be of high quality. The process is reliable by means of clean and accurate molding.

Aerospace

Components used in the airplanes need precision and should be durable. It is essential that repetition must be done in an unvaried way.

Consumer Products

Metal and household products have been enjoying the benefits of rapid and inexpensive production.

Industrial Equipment

Machines, covers and connectors used in factories are in molded parts that are required to take care of heavy usage.

Repmold versus Traditional Molding.

Speed Comparison

Conventional molding requires more time to set up. Repmold saves time and improves preparation.

Cost Efficiency

The methods used in the past can involve a series of molds. It is a contemporary style that emphasizes on reusability and efficiency.

Consistency

The older systems vary due to their manual adjustments. Repmold produces consistent and reliable outcomes.

Environmental Impact

Reduced volume of waste results to a reduced footprint. This process in many companies is adopted towards sustainable manufacturing.

Selection of the correct Materials.

Thermoplastics

They are powerful, light, and soft to mould. Ideal for high volume parts.

Resins

Excellent in a polished finish and exquisite design. These are commonly used in medical and consumer products.

Composites

Offer power and reliability. Applicable in aerospace and automotive applications.

The right choice of material enhances performance and increases the product life.

How to Repmold your Business.

Evaluate Your Needs

Research on your production volume, budget and design, specifications. All products do not require the same setup.

Invest in Quality Tooling

Good molds are long lasting and accurate. Defects will occur due to poor tooling.

Train Your Team

Machines and safety procedures should be familiar to the operators. Skilled teams reduce errors.

Test Before Scaling

Start with prototypes. Check the process and then proceed to large scale production.

Monitor Performance

Costs, speed and quality of track. You are constantly adding value to your system and this makes it efficient.

Read More Like: Matarecycler

Popular Problems and Resolutions.

Mold Wear

Ciccular movements are destructive. This problem is solved through regular inspection and maintenance.

Material Defects

Weak parts come as a result of poor quality raw materials. Select reliable suppliers at all times.

Temperature Control

Faulty heat parameters influence form. Stability automated controls.

Production Delays

Carrying extra time and tools saves time.

Repmold is smooth and dependable with the right management.

Repmold Technology Future Trends.

Automation

Robotics save on manual labor and enhance precision.

Smart Monitoring

Real-time performance is monitored. Problems are detected early.

Sustainable Materials

Plastics and recycled materials which are eco friendly are on the increase.

Digital Integration

Software links design, production and quality systems to enhance more efficiency.

These advances enhance repmold as more powerful and accessible to international manufacturers.

SEO Benefits of manufacturing companies.

Marketing is also backed up by the use of modern solutions. Companies that provide repmold services win more customers since they guarantee clients speed, accuracy, and cost reductions. Organic traffic is created by such keywords as rapid prototyping, custom molding, precision manufacturing, and industrial replication. Optimized contents assist the businesses in accessing the foreign market and gaining trust on the internet.

Conclusion

The contemporary industries can not lean on the slow or stale means of production any more. The success is contingent upon speed, precision and cost control. Repmold offers a clever answer to this problem through the integration of precision and effectiveness in production cycles. It assists businesses to minimize wastage, enhance quality as well as scaling production without incurring heavy investments. At small companies and at large factories this process helps to maintain the same results and the same performance in a reliable way. It is within the power of companies, by implementing repmold technology, concentrating on smart tooling, professional teams and good materials, to remain competitive, please the customers, and expand steadily in the current demanding global market place with certainty.